郑志永教授

个人简介

1996年毕业于浙江水产学院食品工程专业;2001年毕业于无锡轻工大学,获发酵工程专业硕士学位,2005年毕业于浙江大学,获化学工程与技术专业博士学位,随后到江南大学工作,2007年为江南大学副教授,2018年为江南大学教授。2009年在英国Newcastle University upon Tyne从事生物过程强化和微反应器的访问学者研究。江苏省“六大人才高峰”高层次人才培养选拔对象,中国化工机械动力技术协会搅拌技术专业委员会委员。

教育经历

1992.9-1996.7 浙江水产学院食品工程专业 学士

1996.7-1998.9 浙江水产综合厂 助理工程师

1998.9-2001.3 无锡轻工大学发酵工程专业 硕士

2001.9-2004.9 浙江大学生物化工专业 博士

2007.7-至今 江南大学 硕士生导师

2004.10-2018.5 江南大学 副教授

2018.5-至今 江南大学 教授

招生专业

环境工程

研究领域

研究方向是生物过程工程和生物反应器。致力于研究高含有机物污泥和太湖蓝藻泥的安全高效处理、减量化和资源化,开发高效生物反应器并应用于环境工程实践。近五年承担和参与国家支撑计划、科技重大专项、国家自然科学基金等项目。共发表SCI论文40多篇,授权发明专利15项,其中美国专利2项。

研究领域一:生物过程工程

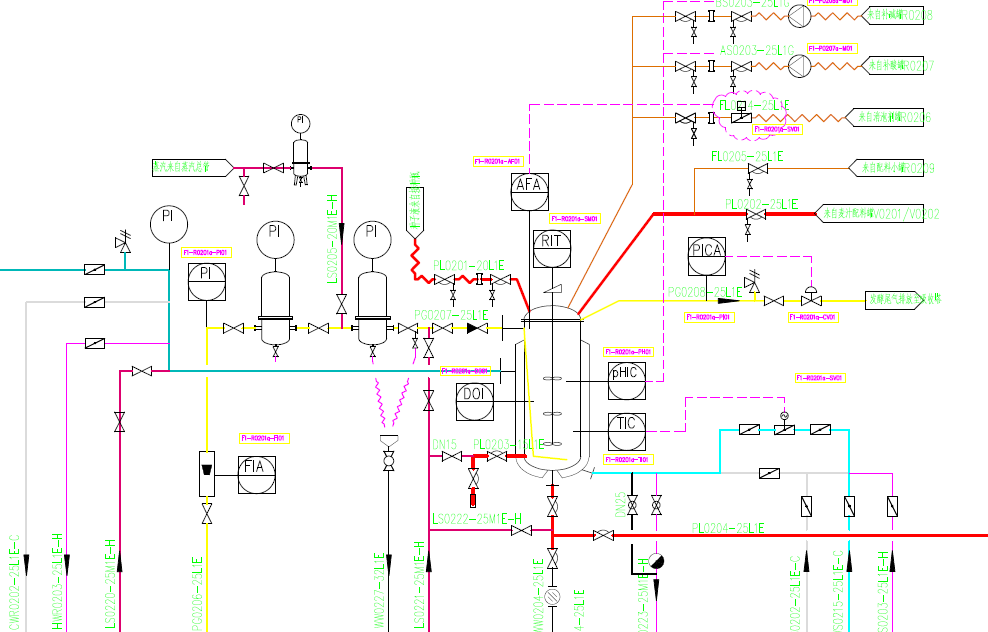

图1. 某生物产品生产过程的PID工艺流程图

图2. 生产车间一角

(1) Zheng Z-Y, Wang S-Z, Li G-S, Zhan X-B, Lin C-C , Wu J-R, Zhu L. A new polysialic acid production process based on dual-stage pH control and fed-batch fermentation for higher yield and resulting high molecular weight product. Applied Microbiology and Biotechnology, 2013, 97(6): 2405-2412.

(2) Yang L-B, Dai X-M, Zheng Z-Y, Zhan X B. Proteomic analysis of erythritol-producing Yarrowia lipolytica from glycerol in response to osmotic pressure. Journal of Microbiology and Biotechnology. 2015, 25(7):1056-1069.

(3) Zhang L H, Liu H, Zheng Z Y, Ma H J, Yang M, Liu H B. Continuous liquid fermentation of pretreated waste activated sludge for high rate volatile fatty acids production and online nutrients recovery. Bioresource Technology, 2018, 249:962-968.

(4) Liu H, Han P, Liu H, Zhou G J, Fu B, Zheng Z Y. Full-scale production of VFAs from sewage sludge by anaerobic alkaline fermentation to improve biological nutrients removal in domestic wastewater. Bioresource Technology, 2018,206:105-114.

(5) Yang L-B, Zhan X-B, Zheng Z-Y, Wu J-R, Gao M-J, Lin C-C. A novel osmotic pressure control fed-batch fermentation strategy for improvement of erythritol production by Yarrowia lipolytica from glycerol. Bioresource Technology, 2014.1.1, 151: 120~127.

(6) Li J, Zhu L, Lu G X, Zhan X-B, Lin C-C, Zheng Z-Y. Curdlan beta-1,3-gluco- oligosaccharides induce the defense responses against Phytophthora infestans infection of potato (Solanum tuberosum L. cv. McCain G1) leaf cells. PLos One, 2014, 9(5): e97197.

(7) Gao M J, Wang C, Zheng Z Y, Zhu L, Zhan X B, Lin C C. Improving arachidonic acid fermentation by Mortierella alpina through multistage temperature and aeration rate control in bioreactor. Preparative Biochemistry & Biotechnology, 2016, 46(4): 360~367.

(8) Wu J R, Lu S Z, Zheng Z Y, Zhu L, Zhan X B. Modification with polysialic acid-PEG copolymer as a new method for improving the therapeutic efficacy of proteins. Preparative Biochemistry & Biotechnology, 2016, 46(8): 788~797 ;

(9) Li J, Zhu L, Zhan X-B, Xu M, Lin C-C, Zheng Z-Y, Li W-J. Purification and characterization of a new endo-beta-1,3-glucanase exhibiting a high specificity for curdlan for production of beta-1,3-glucan oligosaccharides. Food Science and Biotechnology, 2014.6, 23(3): 799~806.

(10) Li J, Zhu L, Zheng Z-Y, Zhan X-B, Lin C-C, Zong Y, Li W-J. A new effective process for production of curdlan oligosaccharides based on alkali-neutralization treatment and acid hydrolysis of curdlan particles in water suspension. Applied Microbiology and Biotechnology, 2013, 97(19):8495-8503.

(11) Zhang H-T, Zhan X-B, Zheng Z-Y, Wu J-R, English N, Yu X-B, Lin C-C. Improved curdlan fermentation process based on optimization of dissolved oxygen combined with pH control and metabolic characterization of Agrobacterium sp ATCC 31749. Applied Microbiology and Biotechnology, 2012, 93(1): 367~379.

(12) Zheng Z-Y, Yao S-J, Zhan X, Lin C C. Improvement of hEGF production with enhanced cell division ability using dissolved oxygen responses to pulse addition of tryptone. Biotechnology and Bioprocess Engineering, 2009, 14(1): 52-59.

(13) Zheng Z-Y, Lee J W, Zhan X B, Shi Z, Wang L, Zhu L, Wu J-R, Lin C C. Effect of metabolic structures and energy requirement on curdlan production. Biotechnology and Bioprocess Engineering, 2007 , 12(4): 359–365.

(14) Zheng Z-Y, Lee J W, Zhan X B*, Shi Z P, Wang L, Zhu L, Wu J R, Lin C C. Effect of metabolic structures and energy requirements on curdlan production by Alcaligenes faecalis. Biotechnology and Bioprocess Engineering, 2007, 12,(4): 359-365.

(15) Zheng,Z Y, Jiang Y, Zhan X B, Ma L W, Wu J R, Zhang L M, Lin C C. An increase of curdlan productivity by integration of carbon/nitrogen sources control and sequencing dual fed batch fermentors operation. Applied Biochemistry and Microbiology, 2014, 50(1):44–51.

研究领域二:生物反应器创新设计和开发

1、螺旋筛板气升式反应器

A. 气液传质效率显著提高;

B. 气泡更小,显著提高气液相界面的比表面积;

C. 径向、轴向的宏观混合和微观混合得到强化;

D. 反应器具有更好的操作弹性;

E. 气体耗量低,流场剪切温和;

F. 螺旋通道两端开放,清洗和维护很方便;

G. 适用于丝状菌、藻类细胞和植物细胞等悬浮培养过程,也适用于环境工程中的生物曝气 过程以及其它气液两相或气液固三相化学反应过程。

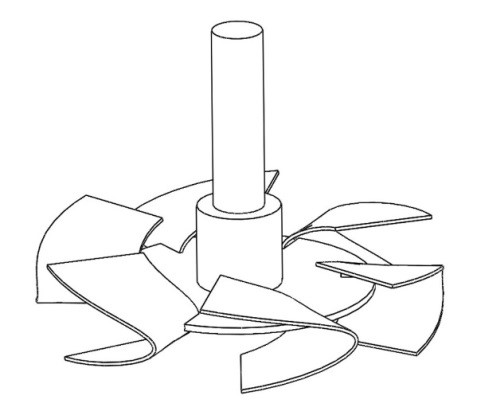

2、装配扇环抛物面桨叶的搅拌桨

A. 发明了一种新型气液分散搅拌桨,可应用于的通风发酵罐中的径向流搅拌器;

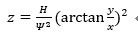

B. 搅拌桨叶片曲面方程:

C. 功耗更低;

D. 氧传质效率更高。

(1) Zheng Z Y, Chen Y Q, Zhan X B, Gao M J, Wang Z F. Mass transfer intensification in a novel airlift reactor assembly with helical sieve plates. Chemical Engineering Journal, 2018, 342: 61–70.

(2) Zheng Z Y, Sun D D, Zhan X B, Gao M J. Gas-liquid dispersion impeller assembly with annular sector-shaped concave blades, US Patent, 2018/ 0117544(B).

(3) Zheng Z Y, Chen Y Q, Zhan X B, Gao M J. Airlift reactor assembly with helical sieve plate. US Patent, 2018/ 119083 (A1).

(4) Zheng Z Y, Sun D D, Li J, Zhan X B, Gao M J. Improving oxygen transfer efficiency by developing a novel energy-saving impeller. Chemical Engineering Research and Design, 2018, 130:199-207.

(5) Zheng Z Y, Yao S J, Lin D-Q. Using a kinetic model that considers cell segregation to optimize hEGF expression in fed-batch cultures of recombinant Escherichia coli. Bioprocess and Biosystems Engineering, 2005. 27:143-152.

(6) 詹晓北, 郑志永, 高敏杰, 丁春华. 一种应用于发酵罐的错流导向式搅拌桨. 中国发明专利, 201310577861.1.

(7) 郑志永, 王子凡, 詹晓北, 高敏杰. 一种高效传质、传热的大规模气液和气液固反应器装置. 中国发明专利, 201610496423.6.

(8) 郑志永, 孙东东, 詹晓北, 章文劼, 章金元, 高敏杰. 一种气液分散搅拌装置. 中国发明专利, 201610639771.4.